- Home >

- Products

-

Pilot Freeze Dryer with 10kg Capacity

Lab scale freeze dryer or Pilot freeze dryer is used for sample test and freeze drying processing research, it can be use all kinds of field, include food, meat, vegetables, fruit, pet food, herbs, sea food, etc. of course, it can be used for chemical field, too. Such as aerogel, Insulation brick, firebrick, battery and so on. Our lab scale freeze dryers have been exported to more than 20 countries, they are popular to all customers, some lyophilizer are used for processing research in university, institute department, some customers use it at home.

-

Fruit Freeze Dryer LG200 sale price

The freeze dryer is suitable for all kinds of fruit freeze drying product, it adopts Aero space technology and high standard manufacturing process. Generally, we product LG200 model freeze drying machine more than 20 sets per year, and we have exported this model to the USA, Germany, Poland, Thailand, etc. The lyophilizer is particularly suitable for large-volume fruit products, has the advantages of short freeze-drying time and low energy consumption.

-

Combination Freeze Dryers with Lower Energy Consumption

Combined freeze-drying equipment is a combination of several sets of freeze-drying equipment, so that some ancillary equipment can be made into a common part, in the investment cost is relatively low, equipment operation is more energy saving, personnel operation cost is also relatively low. Combined freeze dryers include 2xLG100, 4xLG100, 6xLG100, 8xLG100, etc. It is suitable other lyophilizer models, too

-

Middle Freeze Dryer with 900kg Capacity

Medium lyophilization equipment is usually used for small and medium-sized enterprises with a certain production scale. The feeding capacity of a single batch is about 1 ton, and one or two batches can be made with a drying chamber every day. Its advantages, flexible use of equipment, low energy consumption. The number of pretreatment needed for production is not large, and it is easy to operate the freeze-drying process. This set of equipment is designed to consider the user's output and energy consumption and other aspects of cost performance, very popular with customers.

-

Spiral Freezer

Spiral freezing machine is a compact structure, wide application area, small area, large freezing capacity energy-saving fast freezing equipment, is currently used in domestic and foreign food processing enterprises for frozen meat and other frozen products thickness, large volume, high feeding temperature first choice. How to choose suitable IQF machine? 1. Determine the type and quantity of frozen food; 2. Determine the time required for quick freezing; 3. Select refrigeration mode and equipment; 4. Determine the basic size. The basic composition of Enclosure, refrigeration system, transmission parts, electronic control system, etc. The main parameters: Reputation output (pasta), freezing time (min), average incoming temperature, shipping center temperature, average temperature in the warehouse, adjustable time range, cooling capacity (kw), electric power of quick-freezing machine, defrosting method/cycle, external size and weight.

-

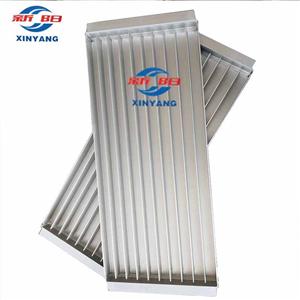

Customized aluminum ribbed Trays

Aluminum ribbed trays are suitable for all kinds of product for freeze drying processing, Because the plate has more room for heat transfer, the drying time of the product is shorter. So, it can save more energy consumption during freeze drying or drying period. We can design and build according to your requirement in detail.

-

Small Freeze Dryer with 140kg Capacity

The loading capacity of LG10 is 130~150kg/batch, It is suitable for small and medium-sized enterprises to invest a small amount in freeze-dried products to see if their new products meet the needs of the market and customers. If the market prospects are good, in the future to consider greater output of lyophilization equipment. Advantages of LG10 lyophilizer: low investment cost, small floor space, simple equipment maintenance and operation, investment cost recovery, etc.

-

Batch Vacuum Fryer

Vacuum frying machine can be used for dewatering of various vegetables, fruits and other products. Our vacuum frying equipment adopts Dutch technology, as well as many years of aerospace processing quality. Thus, the stability and reliability of equipment operation are guaranteed.

-

Lab scale vacuum fryer for snacks VF10TS

VF10TS Type vacuum fryer for laboratory, batch type, fry and centrifuge in one, side-open vacuum fryer. It’s suitable for many different kinds of fruits and vegetables. Vacuum Fryer allows the moisture inside food materials to be removed under high vacuum and low temperature. The device can be used for all types of food materials, and the high-vacuum, low-temperature frying preserves the original taste of the ingredients. The cooking process is safer as the device does not change the physical properties of the ingredients, which commonly occurs when frying at a high temperature. This vacuum fryer adopts Dutch technology with more than 20 years experience.