- Home

- >

- Products

- >

- Freeze Dryer

- >

- Pet food vacuum freeze dryer of lyophilizer

Pet food vacuum freeze dryer of lyophilizer

Brand :XINYANG

Product origin :CHINA

Delivery time :Within 3 Months

Supply capacity :100 Sets

Raw food and freeze dried pet food are almost the same. If you want to give your pets the same nutrients as raw food, freeze drying might be the best choice for you.

As the first choice for pet food processing, Xinyang freeze-drying equipment is popular among pet food manufacturers. More and more customers become Xinyang's partners.

Xinyang freeze-drying machine has a large feed volume in a single batch, and the freeze-drying time is short. The cold trap will automatically defrost during the freeze-drying process, which can be continuously produced, which greatly reduces the processing cost of the product.

What is Freeze Drying processing?

Freeze drying is the process of removing liquid from an item, such as food, pet food, chemcial products and so on, to help shelf life, reduce weight, and preserve quality. Due to the expense of freeze drying, it's the best used for premium products of premium quality.

Freeze drying begins with freezing the product in short time and subjecting it to vacuum pressure to remove the solvent content (usually water) from the product. The product is then heated, which allows the solvent to evaporate through a process known as sublimation processing.

For example, in the case of freeze dried food, a food item's texture, flavor, and nutritional content remain intact. Freeze-drying also greatly reduces the weight of the food, making it easier to transport and store.

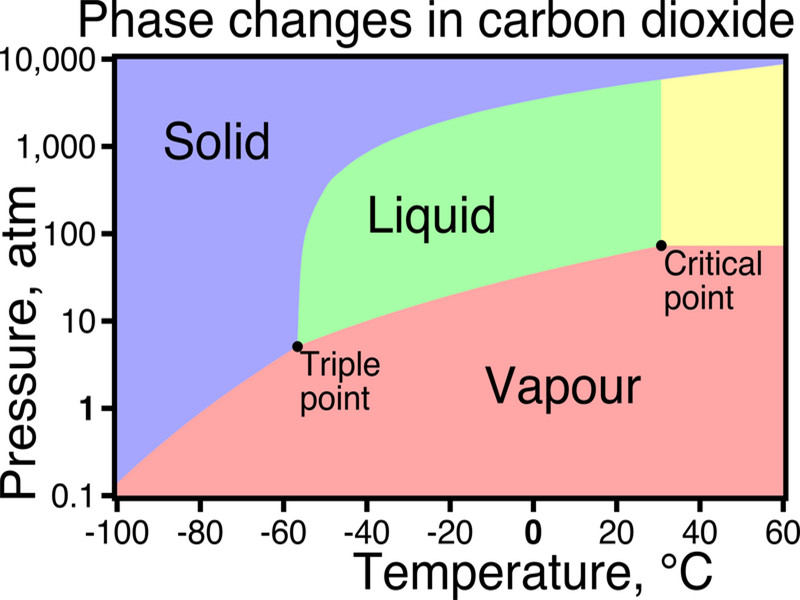

What is triple point?

In physics and chemistry, the triple point of a substance is the temperature and pressure at which three phases (gas, liquid, and solid) of that substance may coexist in thermodynamic equilibrium.

The advantage of Xinyang freeze dryers

1. Xinyang freeze-drying machine has a large feed volume in a single batch, and the freeze-drying time is short. The cold trap will automatically defrost during the freeze-drying process, which can be continuously produced, which greatly reduces the processing cost of the product.

2. Xinyang freeze dryer adopts the international advanced design concept and integrates the technology of vacuum heating, refrigeration and melting. The radiation heating method greatly improves the heating uniformity of the product. The freeze-dried product after rehydration is almost the same as the fresh product. quality.

Technical specification of large freeze dryers

| Paramters | LG125 | 2xLG125 | 4xLG125 | LG200 | 2xLG200 | 4xLG200 |

| Heating area (m2) | 125 | 250 | 500 | 200 | 400 | 800 |

| Loading capacity (Kg/batch) | 1500 | 3000 | 6000 | 2500 | 5000 | 10000 |

Water condensation capacity (Kg/h) | 275 | 550 | 1100 | 440 | 880 | 1760 |

Refrigeration capacity (Kw) needed (T0=-40℃, Tk=+35℃) | 200 | 320 | 640 | 320 | 560 | 1100 |

| Steam consumption (Kg/h) | 400 | 680 | 1200 | 690 | 1300 | 2580 |

| Rated power supply (Kw) | 56 | 85 | ||||

| Heating media | Deionized water | |||||

| Heating mode | Double side radiation | |||||

| Heating plates temperature Range (℃) | Ambient temperature ~+120℃ | |||||

Why to choose freeze drying processing for pet foods of lyophilization?

Unlike the dehydration process, freeze drying is much better because it keeps the food in its original condition. It doesn’t change the food’s cellular make-up, which happens in the dehydration process since low heat is used. So yes, freeze-dried pet food is good for your pets because it keeps the original nutrients of the food.

One of the most important factors to consider when producing or buying pet food is the ingredients. Most freeze dried pets foods contain raw food without any preservatives to retain nutrients and vitamins.

The difference among freeze dried products and hot air drying & mixed products

| Ingrendient | Freeze dried products | Air dried products | Mixed products | |

Nutritional indicationrs | Crude protein | 80% | 56% | 26% |

| Crude fat | 7.5% | 2.5% | 2.5% | |

| Crude fiber | 0.1% | 0.5% | 1% | |

| Crude Ash | 5% | 7% | 3.5% | |

| Moisture | 4.9% | 18% | 35% | |

| Others | 2.5% | 16% | 32% | |

Physical Indicators | Vitamin | 75% retained | 10% retained | 35% retained |

| Shape | Original shape | Shrinkage | Changed 90% | |

| Color | Original color | Darker color | Colorant | |

| Taste | Crispy authentic flavor | Hard | Moderate | |

| Preservatives | None | Antioxidants | Preservatives added | |

| Shelf life | > 36 months | 18 months | 18 months |

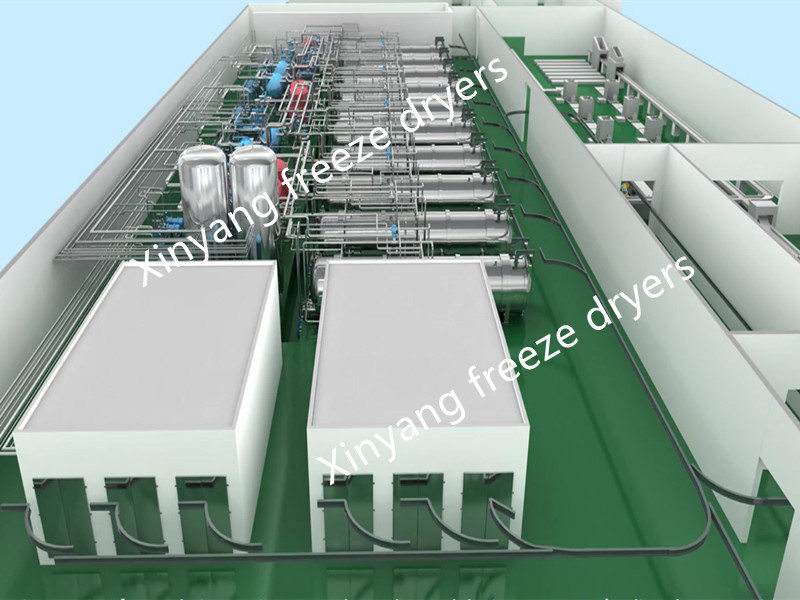

3D View of freeze drying machine

This is a partial display of the three-dimensional space of the freeze-drying equipment, mainly to show the composition of the workshop where the freeze-drying equipment is located.

Which parts do Xinyang freeze-drying equipments include?

Xinyang company can design and build Turn-key project of freeze drying plant for the end users;

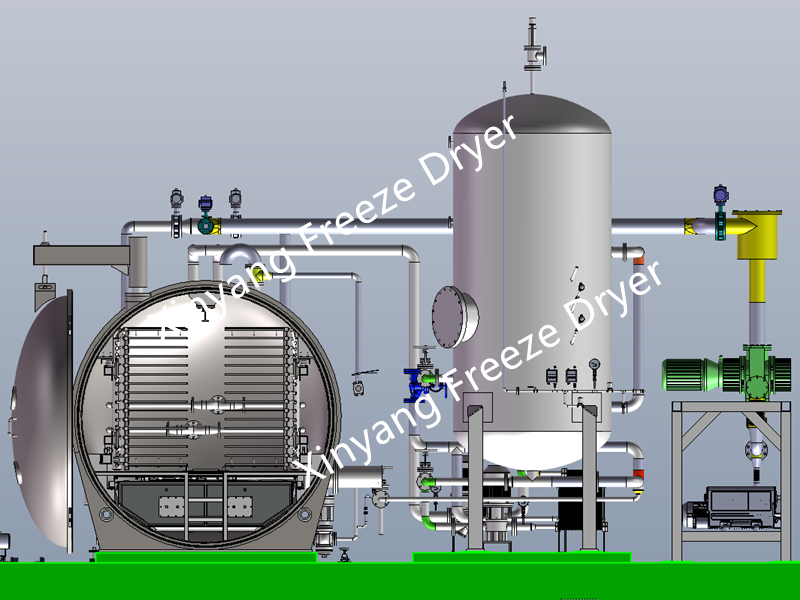

In general, Freeze drying machine shall include vacuum drying chamber, hot water system, vacuum system, de-icing system, monorail system, blast freezer, refrigeration system, control system with trolleys and trays, etc.

The customer can choose the main parts of lyophiliation machine according to real requirement, Xinyang will redesign based on the clients customized requirement.

Why is Xinyang's freeze-drying equipment trustworthy?

In the process of designing, manufacturing, and installing freeze-drying equipment, we will not miss any tiny details, and consider as much as possible for users to achieve perfection, whether the equipment's after-sales service can be guaranteed in time, and demonstrate the responsibility of a responsible supplier. It is also the successful summary of Xinyang's many years of export experience.

As a manufacturer of freeze-drying equipment for more than 30 years, Xinyang always puts the interests of customers in the first place. The parts of freeze-drying equipment are selected from international or domestic well-known brands, while providing sufficient spare parts. Customer needs are our task. Xinyang The company always maintains technical support and service for customers.

Freeze dried pet food is a relatively new type of Pet food. Through special processing technology, it retains the original flavor and nutrients of the food, and effectively extends its shelf life. In recent years, this type of food has attracted more and more pet owners' attention and favor in the Pet food market. This article will explore the process research and market prospects of pet freeze-dried food.

The production process of pet freeze-dried food mainly includes collecting raw materials, pre-treatment, freezing, vacuum drying, and packaging. Firstly, selecting high-quality raw materials is the foundation for producing high-quality pet freeze-dried food. Whether it's meat, seafood, or vegetables, it's important to choose fresh and healthy ingredients. Next, pre treat the ingredients, including cleaning, disinfection, and cutting. Then, the pre processed ingredients are placed in a cold storage for freezing to maintain their original nutritional composition and flavor.

Overall, pet freeze-dried food is made through a unique process that preserves the original taste and nutritional components of the ingredients, while also providing convenience and portability. This type of food has broad prospects in the Pet food market, which is in line with modern people's pursuit of pet health and quality of life. For pet owners, freeze-dried food is not only a food choice, but also a concern and care for their pet's health and happiness.

1. Freeze-dried products retain their natural taste, aroma and colour without losing their nutritional value; 2. Freeze dried products do not contain any preservatives; 3. The elimination of water from the primary product significantly reduces the growth of microorganisms and bacteria; 4. Freeze-dried products are light, easy to transport and have a long shelf life....more

-

Download

- Xinyang Catalogue.pdf