-

Spiral Freezer

Spiral freezing machine is a compact structure, wide application area, small area, large freezing capacity energy-saving fast freezing equipment, is currently used in domestic and foreign food processing enterprises for frozen meat and other frozen products thickness, large volume, high feeding temperature first choice. How to choose suitable IQF machine? 1. Determine the type and quantity of frozen food; 2. Determine the time required for quick freezing; 3. Select refrigeration mode and equipment; 4. Determine the basic size. The basic composition of Enclosure, refrigeration system, transmission parts, electronic control system, etc. The main parameters: Reputation output (pasta), freezing time (min), average incoming temperature, shipping center temperature, average temperature in the warehouse, adjustable time range, cooling capacity (kw), electric power of quick-freezing machine, defrosting method/cycle, external size and weight.

-

Mesh Belt Tunnel Freezer

The advantage of tunnel freezer

-

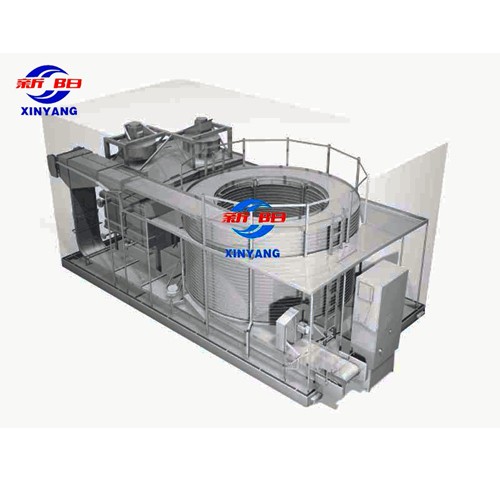

Self-Stacking Spiral Freezer

Self-stacking spiral freezer incorporate interlocking self-stacking belt, which tier by tier stacks on robust chain-ball driving system, completed with wire belt mesh and self-supporting side links, belt stack forms special ducting and enclosed freezing zone and works as circulation loop. Controlled cold air travels around food products while circulating through belt stack from the top down, high heat exchange mini mizes freezing time and dehydration, achieves maximum throughput in minimal footprint. The spiral components are delivered as pre-assembled modules for quicker installation whilst the refrigeration station can be delivered in complete piece. All electrical and piping connections between the two pieces of equipment are included and commissioned together.

-

Fluidized Bed Freezer

-

Belt Quick Freezer