- Home

- >

- Products

- >

- IQF Machine

- >

- Spiral Freezer

Spiral Freezer

Brand :XINYANG

Product origin :CHINA

Delivery time :Within 3 Months

Supply capacity :100 Sets

Spiral freezing machine is a compact structure, wide application area, small area, large freezing capacity energy-saving fast freezing equipment, is currently used in domestic and foreign food processing enterprises for frozen meat and other frozen products thickness, large volume, high feeding temperature first choice.

How to choose suitable IQF machine?

1. Determine the type and quantity of frozen food;

2. Determine the time required for quick freezing;

3. Select refrigeration mode and equipment;

4. Determine the basic size.

The basic composition of Enclosure, refrigeration system, transmission parts, electronic control system, etc.

The main parameters:

Reputation output (pasta), freezing time (min), average incoming temperature, shipping center temperature, average temperature in the warehouse, adjustable time range, cooling capacity (kw), electric power of quick-freezing machine, defrosting method/cycle, external size and weight.

LX Series Food Quick Freezing Equipment

The stainless steel mesh belt of LX series helical quick-freezing equipment runs in helica type in freezing room, thus to realize quick-freezing of feeding materials. It can be divided into two types: Helical self stacking belt (LXDS) and Helical track (LXGS). Except that the bottom layer belt has track and supporting parts, other belt layers of LXDS are all utilize side plate of next leyer mesh belt as support of upper layer mesh belt, forming a helical stacking, running successively and reciprocally; The transfer mesh belt of LXGS runs on helical track, running successively and reciprocally in helica type. They respectively adopts air circulating of top and side blowing. The range of freezing time is adjustable from 15-60 minutes. This equipment is suitable for quick-freezing flavored food, small package food, meat cut and ice cream etc. It can also apply to marine product, fruit and vegetable which can not be quickly frozen by fluidization.

Main Tech. Para. for LX Series Helical Quick-Freezing Equipment

| Item\Parameter\Model | LXDS-300 | LXDS-500 | LXDS-1000 |

Input capacity | 300 | 500 | 1000 |

Output kg/h | 500(boiled dumplings) | 500(headless shrimp) | 1000(chicken string) |

Feeding temp. ℃ | 15 | 15 | ≤50 |

Outfeeding temp. ℃ | -18 | -18 | -18 |

Cycle cold air tem. without loading ℃ | -35±2 | -35±2 | -35±2 |

Dimension of quick-freezing chamber (m) | 6.6x2.7x2.55 | 9.1x7.2x3.6 | 14.6x5.4x3.4 |

Overall length of quick-freezing equipment (m) | 9.4 | 11.55 | 16.8 |

Refrigerate capacity required (t。=-40℃) kw | 105 | 180 | 216 |

Installed power (kw) | 15 | 20 | 28 |

Features | Self stacking mesh belt | Single drum track helical | Double drum track helical |

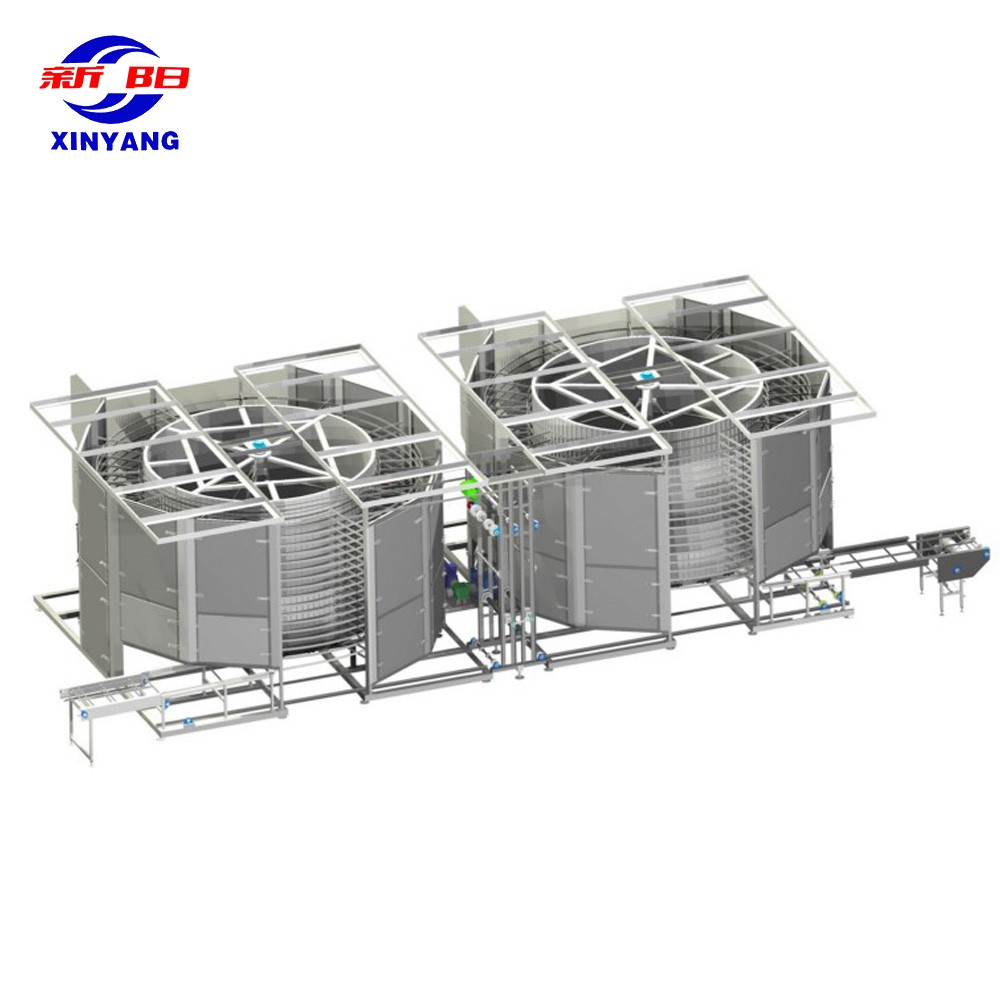

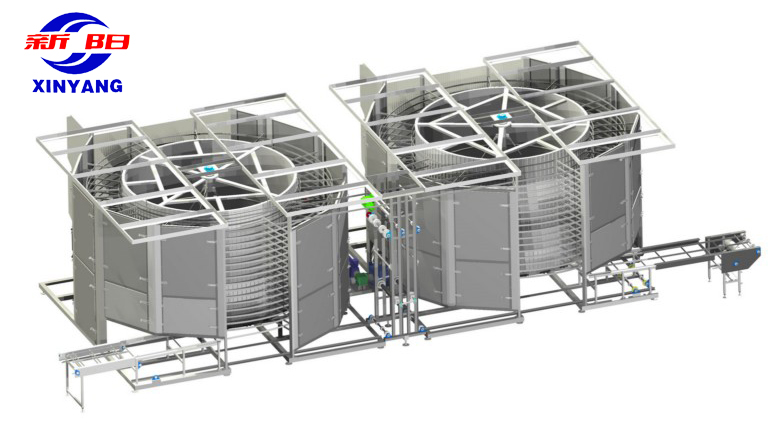

In order to meet market requirements, Xinyang Company researched new double spiral freezer on the basis of experiences in single spiral freezer. It adopts two turning drums, showing the best advantages of spiral freezer.

Advantages of Double Spiral Freezer

◆ High Freezing Capacity

Double turning drums can effectively play advantages of spiral freezer, as such double spiral freezer is highly suitable for large production.

◆ Modernization Design

Inlet and outlet of double spiral freezer are all installed on the bottom of the equipment, so that it can equip with other assembled equipmens achieving modernization production.

◆ More Applicable and Flexible in Various Freezing Products

Double spiral freezer can run separately, which can decrease precooling process and related equipments, finishing precooling and quick-freezing at a time. This equipment is also suitable for bulk foods that need long freezing time.

Main Tech. Para. for SLX Series Double Spiral Quick-Freezing Equipment

| Item Model | SLX-800 | SLX-1000 | SLX-1500 | SLX-2000 |

| Output(Kg/h) | 800 | 1000 | 1500 | 2000 |

| Feeding Temp(℃) | 15 | 15 | 15 | 15 |

| Outfeeding Temp(℃) | -18 | -18 | -18 | -18 |

| Cycle cold air temp when no loading(℃) | 35±2 | 35±2 | 35±2 | 35±2 |

| Installed power(Kw) | 28 | 28 | 37 | 46 |

| Dimension of quick freezing room(L*W*H(m)) | 10.4*7.2*2.85 | 10.4*7.2*3 | 11.05*7.5*3.85 | 11.05*7.5*4.58 |

| Overall length of mesh belt(mm) | 235 | 260 | 370 | 485 |

| Overall wide of mesh belt(mm) | 650 | 650 | 710 | 710 |

| Required Refrigeration capacity(Kw) | 145 | 180 | 260 | 350 |

| Numberof layers | 2*8 | 2*9 | 2*12 | 2*16 |

| Height between layers | 145 | 145 | 180 | 180 |

Packaging and Delivery

Company Profile

Shenyang Aerospace Xinyang Quick freezing Equip. Manuf. Co., Ltd. was founded in 1985, a leading enterprise incorporating the research, manufacturing, sales and services of food processing equipment and freezing technology. Freeze drying equipment and IQF freezing equipment are widely used around the world.

Our team have supported over 1,500 food engineering projects both domestically and abroad, our products have been exported to USA, Canada, Germany, Netherland, Singapore, Thailand, Malaysia, Indonesia, Korea, Myanmar, Chile, Nigeria etc.

Over 30 years’ experience make us expertise in the food processing equipment manufacture, and we’re confidence to provide you with high quality products and also good services.

Shenyang Aero Space Xinyang Quick Freezing Equip. Manuf. Co., Ltd.

Address: No.18-5, Yaoyang Road, Huishan Economic Development Zone, Shenyang, China.

Tel: +86-24-86525079 Fax: +86-24-86520145 www.xysudong.com

1. Freeze-dried products retain their natural taste, aroma and colour without losing their nutritional value; 2. Freeze dried products do not contain any preservatives; 3. The elimination of water from the primary product significantly reduces the growth of microorganisms and bacteria; 4. Freeze-dried products are light, easy to transport and have a long shelf life....more

-

Download

- spiral freezer.rar