- Home

- >

- Products

- >

- Freeze Dryer

- >

- Industrial commercial vacuum freeze dryer with 5000 kg capacity

Industrial commercial vacuum freeze dryer with 5000 kg capacity

Brand :XINYANG

Product origin :CHINA

Delivery time :Within 3 Months

Supply capacity :100 Sets

Industrial commercial vacuum freeze dryer is used for fruits and vegetables freeze drying producing, the loading capacity of combination chamber is 5000 kg/batch.

Many producers of freeze drying products chose this model as the initial plan to start the freeze-drying project, because they want to enter the freeze-drying field in the shortest time.

The choice of freeze-drying equipment is very important, especially for the first time entering the completely unfamiliar freeze-drying field, feasibility analysis and adequate market research become very critical.

Why is the right choice to invest in freeze-drying projects?

In recent years, with the continuous improvement of people's living standards, people's concerns and needs for healthy diets have become very urgent. Freeze-dried foods are exactly in line with the characteristics of healthy diets, not only retaining the nutrition of the products during the freeze-drying process The ingredients are not lost, and it is easy to store and carry, convenient and fast to eat.

Especially since 2020, due to the impact of the new crown epidemic, many changes have taken place in people's appearance and diet, and food that is easy to store and not affected by business is very popular. The market for freeze-dried food is developing more and more, and the demand for freeze-dried food is also increasing. The investment in freeze-drying projects and freeze-drying industry is also increasing, and the industries related to freeze-dried food are valued by investors, and the investment is continuously increased, and the demand for freeze-drying equipment is unprecedentedly high.

The technical specification of large freeze dryer

| Paramters | LG125 | 2xLG125 | 4xLG125 | LG200 | 2xLG200 | 4xLG200 |

| Heating area (m2) | 125 | 250 | 500 | 200 | 400 | 800 |

| Loading capacity (Kg/batch) | 1500 | 3000 | 6000 | 2500 | 5000 | 10000 |

Water condensation capacity (Kg/h) | 275 | 550 | 1100 | 440 | 880 | 1760 |

Refrigeration capacity (Kw) needed (T0=-40℃, Tk=+35℃) | 200 | 320 | 640 | 320 | 560 | 1100 |

| Steam consumption (Kg/h) | 400 | 680 | 1200 | 690 | 1300 | 2580 |

| Rated power supply (Kw) | 56 | 85 | 115 | |||

| Heating media | Deionized water | |||||

| Heating mode | Double side radiation | |||||

| Heating plates temperature Range (℃) | Ambient temperature ~+120℃ | |||||

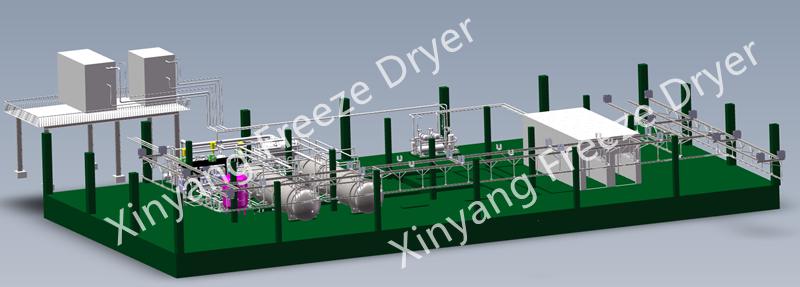

Three-dimensional display of freeze-drying equipment workshop

Vacuum freeze drying equipment include vacuum drying chambers, blast freezers, refrigeration compressor system, hot water system, de-icing system, control system, monorail system and accessory equipments, etc.

The advantage of Xinyang vacuum freeze drying equipments

1. Efficiency of Heating Plates

The material of heating plates is aviation aluminum with anodized on the surface, over 100% heat release to the product by radiation, keeping heating uniformity completely.

2. Double Side Radiation Heating Method

There is a certain distance between the tray and the heating plate, avoiding the direct contact, the product is heated evenly. If the temperature of the heating plates gets higher, this heating method can protect the product from getting burnt.

3. Compact Design

Two alternate cold traps are built in the drying chamber, this leads to the compact structure, no need extra place. Compared to other suppliers, the unique design of de-icing tank requires less space, instead of a large water pool.

4. Saving Water

De-icing tank under the drying chamber, which is connected to the vapor trap. The water used to melt the ice comes from the drying material. So this helps save a huge amount of water from wasting.

5. Stable Efficiency

Alternate vapor trap, continuous de-icing. Double vapor trap are installed under the heating plates in drying chamber. During the drying process, the two cold traps work continuously and alternately.When Cold Trap I is condensing, Cold Trap II is de-icing at the same time, and after some time, they change to each other’s state. The Cold Trap II begins to catch water vapor, the Cold Trap I begins to melt ice on the coil, after melting, the clean coil ready for another condensation cycle. There's no extra time needed for separate ice melting, and that helps to increase the output to a certain extent. Due to CDI (continuous de-icing) technology, the ice layer is usually thin for melting, the surface of the coil tube of the cold trap is always at a lower temperature, the capture efficiency remains relatively high all through the whole drying processing, which ensures high quality of products.

Blast freezers as pre-freezing solution for lyophilization processing

Fresh product needed to be frozen in blast freezers before they were loaded into vacuum drying chambers, this is quite important step to keep product temperature lower than -20℃, it is entire sublimation processing during vacuum drying chamber.

Manufacturing of freeze dryer in Xinyang's factory

All parts of the vacuum freeze-drying equipment are strictly inspected and tested before leaving the factory. After the drying chamber is assembled, a vacuum pressure holding test is performed. The cold trap reversal is tested according to the actual operating conditions, and the trolley assembly is fully loaded, Control panel is inspected, etc.

Freeze dryer accessories - Selection of trolley and tray

Freeze dryer accessories - Selection of trolley and tray

Usually, each set of freeze-drying equipment is equipped with 2 sets of trolleys and trays, In this way, a set of trolley and tray in the drying chamber are undergoing freeze-drying processing, while another set of trolleys and trays can be used for product pre-treatment to prepare for the next batch of freeze-drying processing. Of course, some customers choose 3 or 4 sets of trolleys and trays to meet the needs of continuous operation of freeze-drying equipment on weekends.

Shenyang Aerospace Xinyang freeze-drying machine is China's first self-developed and exported high-end freeze-drying equipment, which has recently achieved impressive performance. As a flagship product of Shenyang Aerospace Xinyang Company, this freeze-drying machine has not only gained widespread recognition in the domestic market, but also successfully entered the international market, making it unique globally.

1. Freeze-dried products retain their natural taste, aroma and colour without losing their nutritional value; 2. Freeze dried products do not contain any preservatives; 3. The elimination of water from the primary product significantly reduces the growth of microorganisms and bacteria; 4. Freeze-dried products are light, easy to transport and have a long shelf life....more