- Home

- >

- Products

- >

- Freeze Dryer

- >

- Pilot Freeze Dryer with 10kg Capacity

Pilot Freeze Dryer with 10kg Capacity

Brand :XINYANG

Product origin :CHINA

Delivery time :Within 3 months

Supply capacity :100 Sets

Lab scale freeze dryer or Pilot freeze dryer is used for sample test and freeze drying processing research, it can be use all kinds of field, include food, meat, vegetables, fruit, pet food, herbs, sea food, etc. of course, it can be used for chemical field, too. Such as aerogel, Insulation brick, firebrick, battery and so on.

Our lab scale freeze dryers have been exported to more than 20 countries, they are popular to all customers, some lyophilizer are used for processing research in university, institute department, some customers use it at home.

Description of Pilot Freeze Dryer LG1.0

Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present.

Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components.

The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking.

This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

LG series freeze drying equipment is manufactured on the basis of experience in areas such as heat transmission, vacuum, refrigeration, pressure vessel manufacturing and automatic control, integrated international advanced technology.

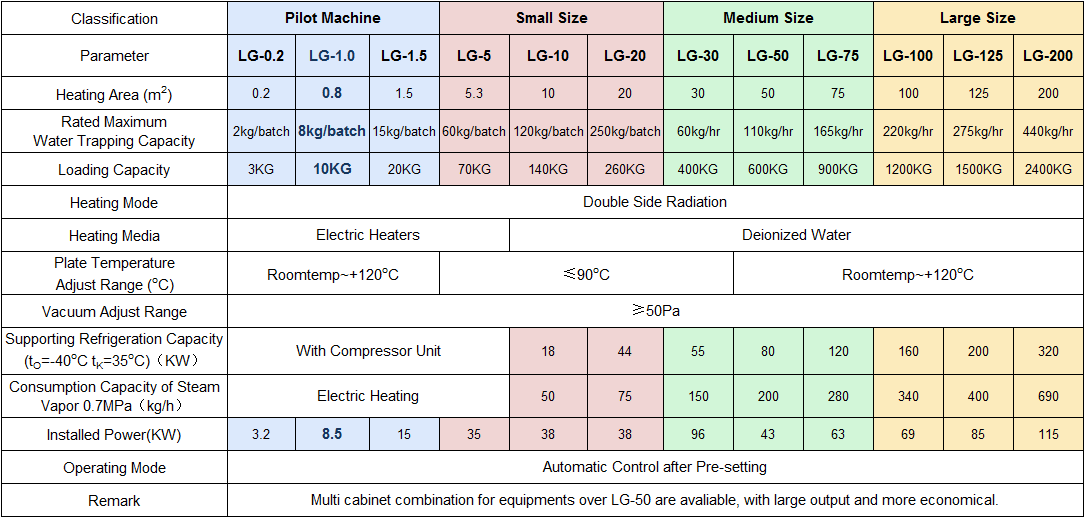

According to the loading capacity of product and its applicability, it can be divided into small(including experimental), medium and large freeze drying equipment.

Small Size Pilot Freeze Dryer

LG1.0 features is easy to clean, control and maintenance. It is operated via a PLC +HMI control system.

All parameters are monitored and stored during freeze drying to provide full documentation of the process. This makes it possible to reuse the test with the same freeze drying characteristics.

At the same time, you can adjust all parameters during drying processing, PLC brand can be customed.

Built-in cold trap with Freon refrigeration system and vacuum system. It’s suitable for large and medium institutions, research institutes and other organizations for samples and crafts research, especially suitable for small production with high value-added. It is suitalbe for home using, too.

The advantages of small freeze dryer:

1. Efficient in heating plates. The material of heating plates is aviation aluminum after being anodized on the surface, releasing over 100% heat from the product by radiation. This makes heat more uniform and complete. High freeze drying capacity of tray surface;

2. Automatic control system. Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle.

3.Radiant heating There is a certain distance between the tray and the heating plate, not directly accepted, the product is heated evenly. good quality.

Specification of Freeze Dryer LG1.0

Weighing device is built in the drying chamber High precision temperature sensor LCD display

Xinyang LG1.0 Specification:

| Dimension (L*W*H) | 2.42*1.07*1.85m |

Heating plate area | 1.0m2 |

Number of heating plates | 5 |

Heating method | Electric heater |

Heating type | Double-sided radiation |

Number of trays | 4 |

Trays material | Aluminum |

Nominal working pressure | 30-100Pa |

| Adjustable temperature rang of heating plate (℃) | Room temperature ~+120℃ |

Supporting refrigeration capacity (To=-40℃ Tk=35℃) (kw) | With compressor unit |

Install power | 8.5kw |

Rated maximum water trapping capacity | 8kg/batch |

| Loading capacity | >10kg/batch |

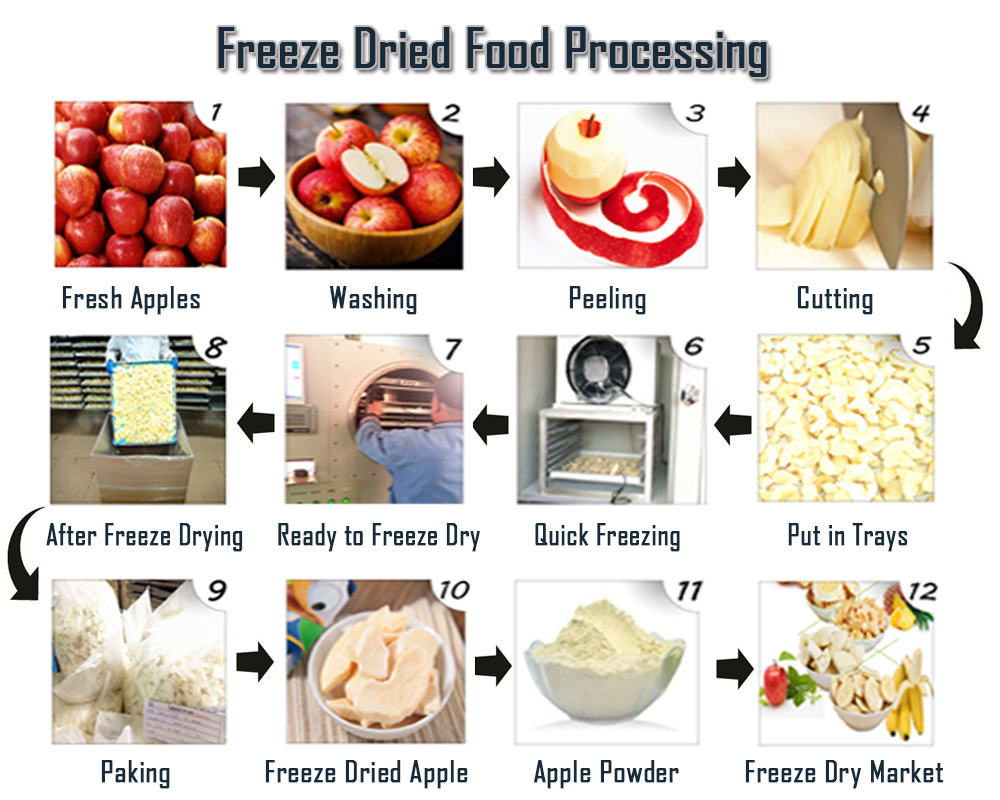

How to produce freeze dried apple?

Assembly before delivery

Manufacturing period

Manufacturing period: 60-100 working days after the contract becomes effective; CE certificate is available.

Technical service

We will offer documents include:

Freeze drying processing include three kinds of products;

Circuit diagram;

Operation instructions;

Working diagram;

Working system elements, etc.

Guarantee

The guarantee period shall be 12 months counting from the date of acceptance certificate.

During this period, if quality problem occurs, the Sellers should guarantee that he will respond and advise solution through verbal or written communication.

Should the problem remain unsolved, the seller would arrange maintenance personnel to the buyer's factory as soon as possible to carry out field maintenance.

If equipment damage is caused by non-operation error, then maintenance is free, otherwise it is for the buyer's account.

Packaging and Delivery

Company Profile

Shenyang Aerospace Xinyang Quick freezing Equip. Manuf. Co., Ltd. was founded in 1985, a leading enterprise incorporating the research, manufacturing, sales and services of food processing equipment and freezing technology. Freeze drying equipment and IQF freezing equipment are widely used around the world.

Our team have supported over 1,500 food engineering projects both domestically and abroad, our products have been exported to USA, Canada, Germany, Netherland, Singapore, Thailand, Malaysia, Indonesia, Korea, Myanmar, Chile, Nigeria etc.

Over 30 years’ experience make us expertise in the food processing equipment manufacture, and we’re confidence to provide you with high quality products and also good services.

1. Freeze-dried products retain their natural taste, aroma and colour without losing their nutritional value; 2. Freeze dried products do not contain any preservatives; 3. The elimination of water from the primary product significantly reduces the growth of microorganisms and bacteria; 4. Freeze-dried products are light, easy to transport and have a long shelf life....more