- Home

- >

- Products

- >

- Freeze Dryer

- >

- Large Freeze Dryer with 2400kg Capacity

Large Freeze Dryer with 2400kg Capacity

Brand :XINYANG

Product origin :CHINA

Delivery time :Within 3 Months

Supply capacity :100 Sets

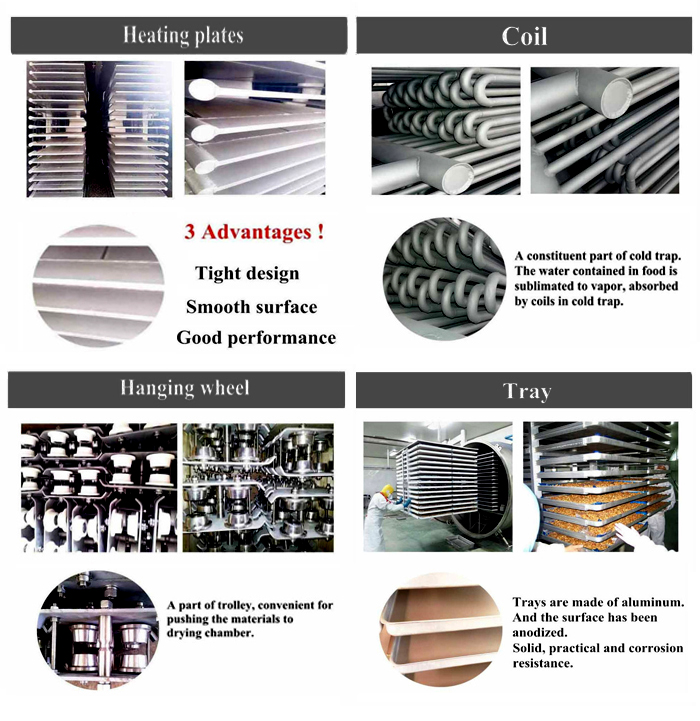

Highlights of freeze-drying equipment

The Xinyang freeze dryer adopts advanced design concepts and is jointly developed by a technical team with more than 10 years of work experience. After nearly 30 years of customer use, it has created a reliable, mature and stable vacuum freeze dryer that customers can trust. Multiple models and different configurations are available for selection, ensuring 24-hour uninterrupted operation and global technical service support. It has advantages such as low energy consumption, high efficiency, and quick investment returns.

Advantages of Freeze Dried Food

1. Taste fresh Freeze-dried foods, like frozen, retain virtually all their fresh-food taste and nutritional content. Freeze-drying removes the water, not the flavor.

2. Look fresh Freeze-dried foods maintain their original shape and texture, unlike dehydrated foods, which shrink and shrivel due to high-temperature processing. Freeze-drying removes water under low temperatures which keeps intact the moisture channels and food fibers. Just add water, and in minutes every fresh food detail returns.

3. Weigh less than fresh Freeze-dried foods have 98% of their water removed. This reduces the food's weight by about 90%. Because of its light weight per volume of reconstituted food, freeze-dried products are popular and convenient for hikers. More dried food can be carried per the same weight of wet food, and remains in good condition for longer than wet food, which tends to spoil quickly. Hikers reconstitute the food with water available at point of use.

4. Stay fresh Freeze-dried foods can be stored at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration.

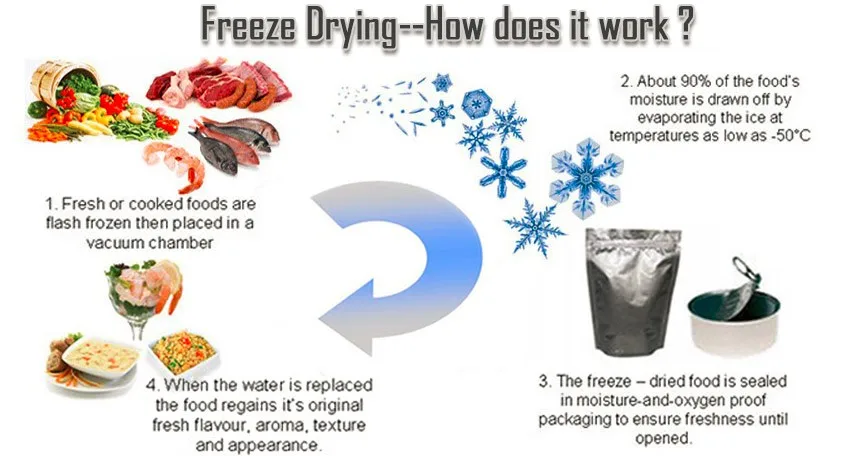

Working Princple of Freeze Drying Machine

Under vacuum condition, material is freeze dried via principle of sublimation. The moisture in the pre-frozen material is directly sublimed from solid state (ice) to gaseous state (vapor), without melting. Freeze dried products are formed to be sponginess, without shrinkage and excellent in rehydration, containing little water only. The freeze dried product in sealed packaging can be stored and transported at room temperature for a long time.

Freeze Dryer can be used to process nearly all kinds of food.

Freeze Dried Food Factory

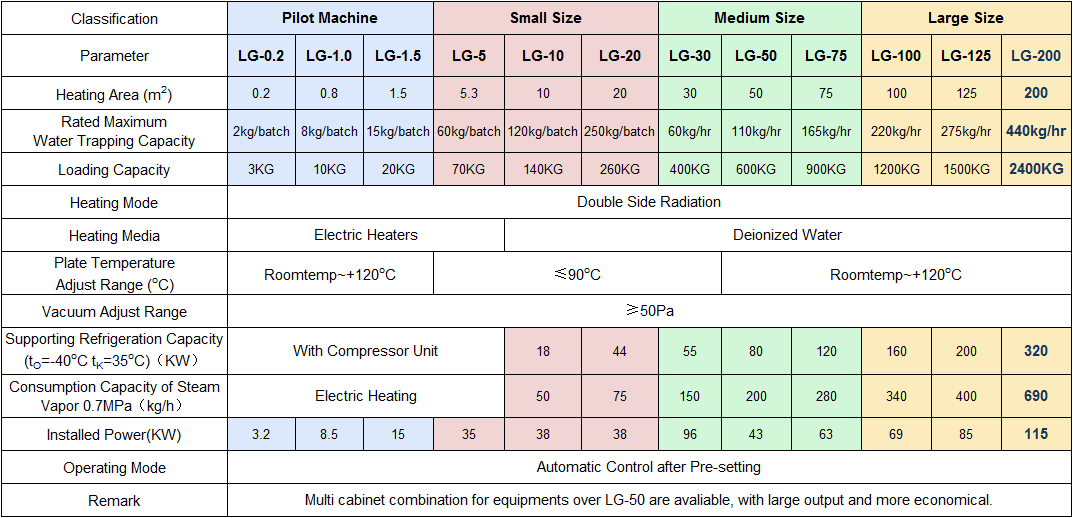

Rated Parameters of LG Freeze Drying Equipment

| Xinyang LG200 Specification: | |

| Steam consumption for the heating | ≥650kg / hour |

| Weight (unloaded) | 25000kg (approx.) |

| Chamber – Overall dimensions | 13.00m long x 2.50m wide x3.30m high (AISI 304 S/S) |

| Vapour Condenser Capacity | 440 kg in a hour |

| Quantity of shelves | 480 trays |

| Usable Shelf Area (m2) | 200 m2 |

| Ice Capacity (kg) | 440 kg/h |

| Shelf Dimensions | 560*680*35mm |

| Shelf Spacing (mm) | 35mm |

| Shelf Temperature | -20oC to +60oC |

| Condenser temperature | - 45oC |

| Low temperature model: shelf freezing to -35oC and vapour condenser temperature -45oC | |

| Free distance between heating plates | 75mm |

| Heating medium | Hot water |

| Heating type | Double-sided radiation |

| Heating medium, max. temperature | 130oC |

| Heating flange | ≥5oC / min speed |

| The speed of cooling | 7a min (from 20oC to – 40oC without load) |

| Cooling medium | Ammonia, freon |

| Material of heating plates | Aluminum |

| Sublimation(max) | 2.5kg/m2h |

| Sublimation(average) | 1.5kg/m2h |

| Power Requirement | 380VAC/50Hz,3phase,100KW(no including refrigerator) |

| Vacuum pressure | 133Pa (working 50pa ~ 133Pa) |

| Material of vapor trap | Stainless steel |

| Water for bathing | Automatic de-icing , no need water |

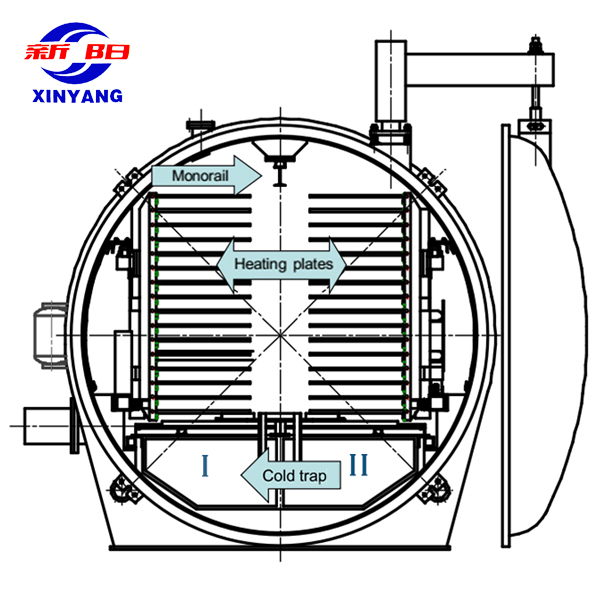

We adopt double alternate cold traps for vacuum freeze dryers, and its working principle of freeze dryer with double alternate cold traps.

Trays with product locate between heating plates, the cold trap I and cold trap II locate under the heating plates inside the drying chamber. When cold trap II is working for condensation of vapor, that comes from the product, and cold trap I is working for defrosting. Low temperature steam (15~25℃)comes from de-icing tank into cold trap I to defrost the ice on the tube, and defrost water goes back to de-icing tank and drained out. Condensation and defrost function change alternately, and controlled by PLC automatically .

So, this kind construction has limitless on product loading capacity, it has much more advantage than other kinds of freeze dryers.

Advantages of LG series Freeze Drying Equipment

1. Efficiency of Heating Plates The material of heating plates is aviation aluminum with anodized on the surface, over 100% heat release to the product by radiation, keeping heating uniformity completely.

2. Double Side Radiation Heating Method There is a certain distance between the tray and the heating plate, avoiding the direct contact, the product is heated evenly. If the temperature of the heating plates gets higher, this heating method can protect the product from getting burnt.

3. Compact Design Double cold traps are built in the drying chamber, this leads to the compact structure, no need extra place. Compared to other suppliers, the unique design of de-icing tank requires less space, instead of a large water pool.

4. Saving Water De-icing tank under the drying chamber, which is connected to the vapor trap. The water used to melt the ice comes from the drying material. So this helps save a huge amount of water from wasting.

5. Stable Efficiency Alternate vapor trap, continous de-icing. Double vapor trap are installed under the heating plates in drying chamber. During the drying process, the two cold traps work continuously and alternately.When Cold Trap I is condensing, Cold Trap II is de-icing at the same time, and after some time, they change to each other’s state. The Cold Trap II begins to catch water vapor, the Cold Trap I begins to melt ice on the coil, after melting, the clean coil ready for another condensation cycle. There's no extra time needed for separate ice melting, and that helps to increase the output to a certain extent. Due to CDI (continuous de-icing) technology, the ice layer is usually thin for melting, the surface of the coil tube of the cold trap is always at a lower temperature, the capture efficiency remains relatively high all through the whole drying processing, which ensures high quality of products.

6. Sanitary Guarantee De-icing system works under a negative pressure condition, the vapor used for melting the ice is from the drying material, which avoid bacterial infections, and it’s much more clean and sanitary.

7. Automatic Control System. Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle, and to save manual resource. And the we can design fully automatic display screen according to your requirements.To process different products, different control curves can be preset in advance, and the equipment will be running accurately according to the preset curve.

Freeze Dried Product Processing

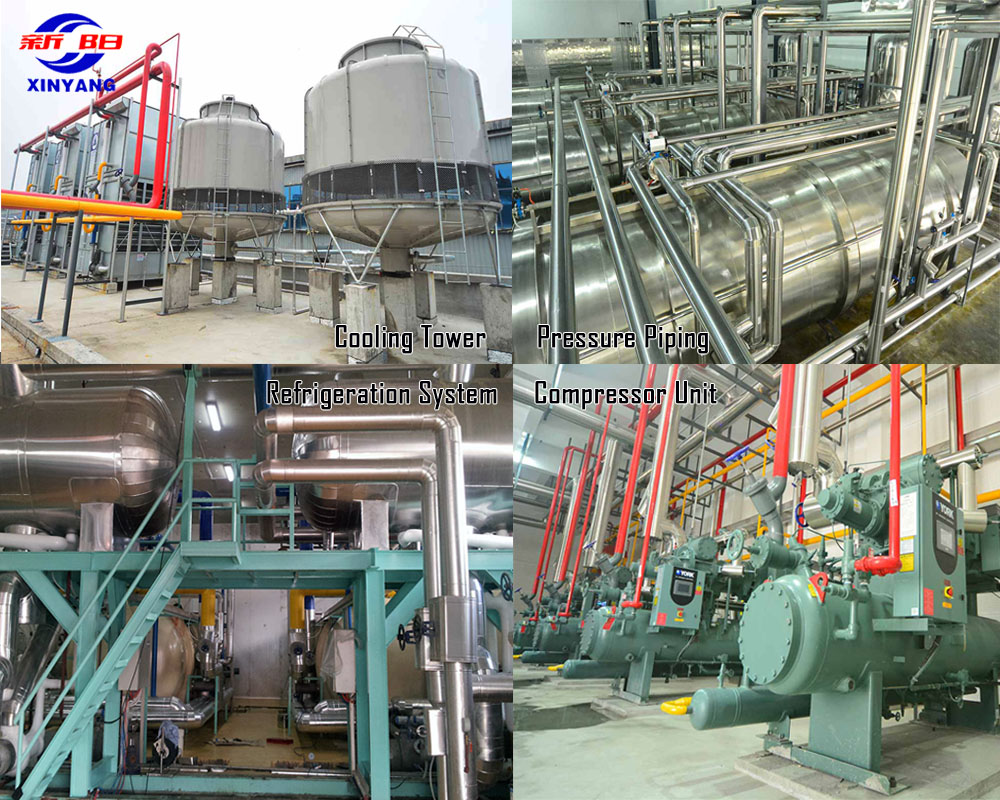

Accessory Equipment

Detail Images

Packaging & Delivery

Company Profile

Shenyang Aerospace Xinyang Quick freezing Equip. Manuf. Co., Ltd. was founded in 1985, a leading enterprise incorporating the research, manufacturing, sales and services of food processing equipment and freezing technology. Freeze drying equipment and IQF freezing equipment are widely used around the world.

Our team have supported over 1,500 food engineering projects both domestically and abroad, our products have been exported to USA, Canada, Germany, Netherland, Singapore, Thailand, Malaysia, Indonesia, Korea, Myanmar, Chile, Nigeria etc.

Over 30 years’ experience make us expertise in the food processing equipment manufacture, and we’re confidence to provide you with high quality products and also good services.

Shenyang Aero Space Xinyang Quick Freezing Equip. Manuf. Co., Ltd.

Address: No.18-5, Yaoyang Road, Huishan Economic Development Zone, Shenyang, China.

Tel: +86-24-86525079 Fax: +86-24-86520145

1. Freeze-dried products retain their natural taste, aroma and colour without losing their nutritional value; 2. Freeze dried products do not contain any preservatives; 3. The elimination of water from the primary product significantly reduces the growth of microorganisms and bacteria; 4. Freeze-dried products are light, easy to transport and have a long shelf life....more