- Home

- >

- News

- >

- Corporate News

- >

- Visiting the Xinyang Freeze-Drying Technology Factory

Visiting the Xinyang Freeze-Drying Technology Factory

Against the backdrop of the booming global pharmaceutical, food and biopharmaceutical industries, freeze drying technology has become a key link in the field of high-end manufacturing due to its advantages of effectively retaining active ingredients in products and extending shelf life.

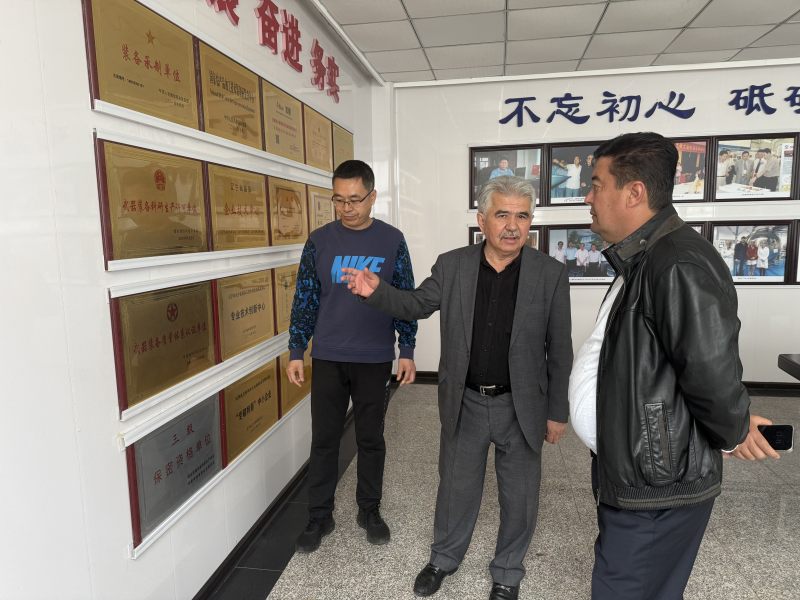

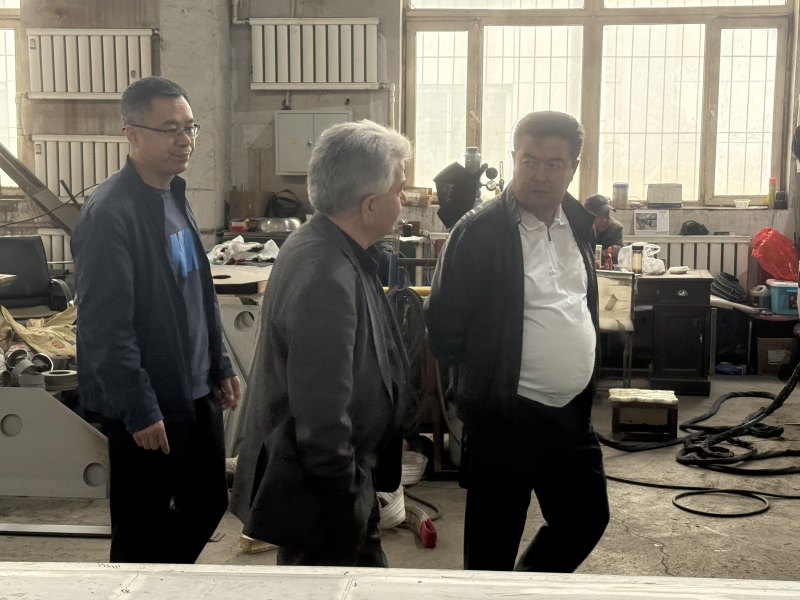

Recently, a delegation of foreign customers visited our freeze drying equipment and freeze dryer company and conducted a two-day in-depth visit and technical exchange on the freeze drying plant and core equipment. This visit not only demonstrated the advanced level of China's freeze drying technology, but also laid a solid foundation for future international cooperation about freeze dryer or freeze drying equipemnt between the two sides.

**I. Customer background and purpose of visit freeze drying equipment or freeze drying machine**

This customer is a well-known enterprise in the region about freeze dryer and freeze drying machine. The core purpose of freeze drying machine and freeze dryer visit is:

1. **Inspect the performance of freeze drying equipment and freeze dryer**: evaluate the freeze dryer or freeze drying machine technical parameters, automation level and compliance of our freeze drying machine or freeze dryer;

2. **Verify the freeze drying machine and freeze dryer production process**: understand the full-process quality control system from raw material freeze drying euipment processing to finished product packaging;

3. **Explore customized cooperation**: seek personalized solutions for its special product needs.

*1. Factory Overview: High-standard freeze drying equipment Production Environment**

The customer delegation first entered the factory, and our engineers introduced:

- **Workshop Partition Design;

- **Environmental Control Qualitative;

- **Intelligent Management about freeze drying technology : The freeze drying system or freeze drying technology traces the entire process of production batches, equipment status, and process parameters.

**Customer Feedback**: The delegation highly recognized the digital management of the workshop about freeze dryer.

**2. Freeze drying equipment display: core technology highlights**

In the freeze drying equipment display area, our company focused on demonstrating the core advantages of the flagship freeze dryer:

- **Precise temperature control technology**;

- Customers observed the real-time data fluctuations of -40℃ rapid freezing and 30℃ sublimation drying on site to verify the stability of the equipment.

- **Energy-saving design**:

- Patented system can reduce energy consumption by 30%. After comparing similar equipment, customers said it was "far beyond expectations".

- **Compliance verification**:

- Display certification documents and third-party verification reports.

**Interactive session**:

-The customer personally operated the touch screen interface to experience the "one-click process recipe call" function and expressed satisfaction with the multi-language support.

**Meeting results**:

The customer confirmed the purchase intention on the spot and planned to start a feasibility study of the customized project.

**Fourth, follow-up of the visit: a milestone in deepening cooperation**

After the visit, our company submitted a personalized technical proposal to the customer, including:

- A freeze drying process validation plan for its products;

- Freeze drying euipment or freeze dryer delivery and training schedule;

- A commitment to localized after-sales service.

**Conclusion**

This visit for our freeze drying technology by international customers is not only an affirmation of our freeze drying technology strength, but also a benchmark case for China's high-end equipment to "go overseas". In the future, we will continue to be driven by innovation and help global customers achieve a leap in product value.