- Home

- >

- News

- >

- Corporate News

- >

- High-tech freeze dryer double alternating vapor trap, CDI technology

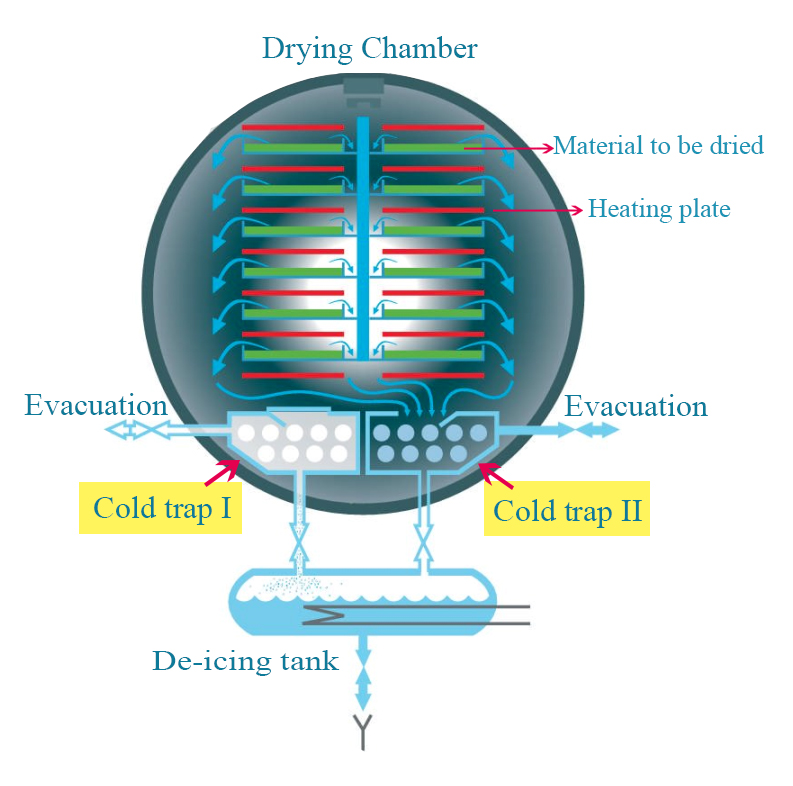

High-tech freeze dryer double alternating vapor trap, CDI technology

The drying chamber of freeze dryer

CDI (continuous de-icing) technology Working Principle of freeze dryer

Double vapor traps are installed under the heating plates in drying chamber of freeze dryer. During the drying process, the two cold traps work continuously and alternately. When Cold Trap I is condensing, Cold Trap II is de-icing at the same time, and after some time, they change to each other's state. The Cold Trap II begins to catch water vapor, the Cold Trap I begins to melt ice which is on the coil, after melting, the clean coil ready for another condensation cycle.

De-icing tank is located under the drying chamber of freeze dryer, which is connected to the vapor trap. Low temperature steam (15~25℃)comes from de-icing tank into cold trap I to defrost the ice on the tube, and defrost water goes back to de-icing tank and drained out. Condensation and defrost function change alternately, and controlled by PLC automatically .

Compact Design of freeze dryer

Double cold traps are built in the drying chamber, this leads to the compact structure, no need extra place. Compared to other suppliers, the unique design of de-icing tank requires less space, instead of a large water pool.

Saving Water of freeze dryer

De-icing tank under the drying chamber of freeze dryer, which is connected to the vapor trap. The water used to melt the ice comes from the drying material. So this helps save a huge amount of water from wasting.

Stable Efficiency of freeze dryer

Alternate vapor trap, continous de-icing. There's no extra time needed for separate ice melting, and that helps to increase the output to a certain extent. Due to CDI (continuous de-icing) technology, the ice layer is usually thin for melting, the surface of the coil tube of the cold trap is always at a lower temperature, the capture efficiency remains relatively high all through the whole drying processing, which ensures high quality of products.

Large Capacity of freeze dryer

Because of construction of the double cold trap and de-icing tank, CDI technology, alternate working vapor trap make it possilble for even large capacity of drying material, but no effects on the quality of the freeze dried product, it has many advantages over other kinds of batch type freeze dryer.