- Home

- >

- News

- >

- Corporate News

- >

- Advantages of Freeze Dried Food

Advantages of Freeze Dried Food

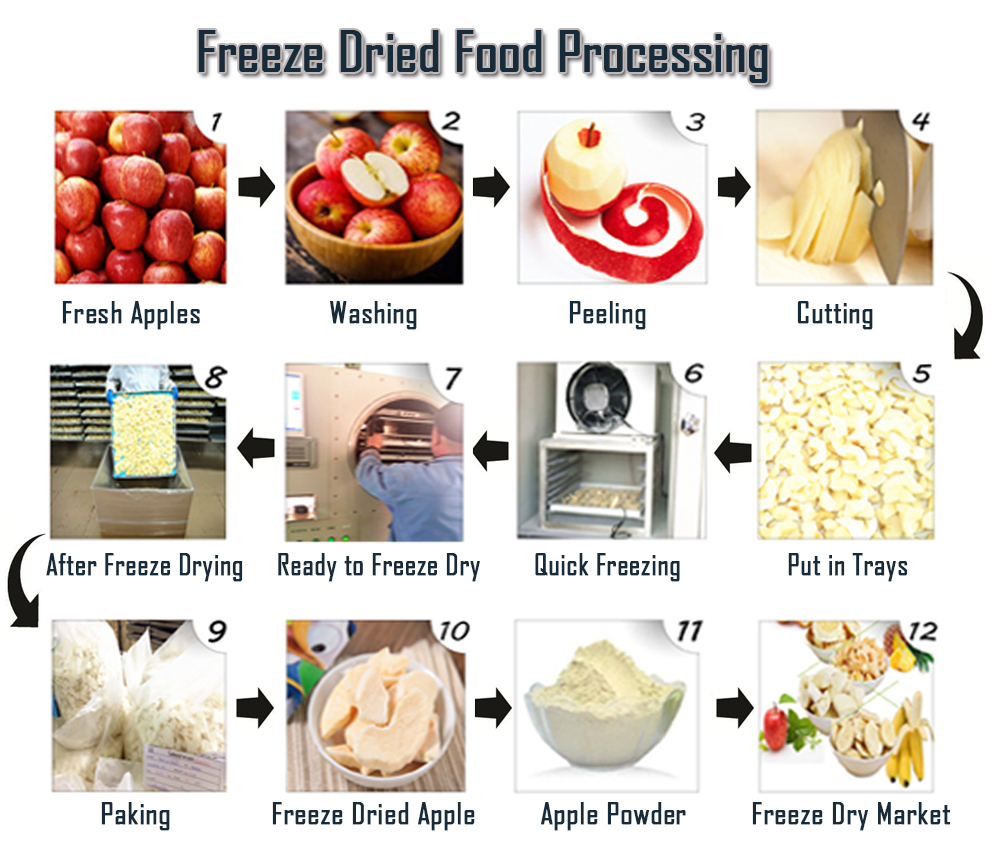

Freeze Drying, also known as lyophilization, is a water removal process typically used to preserve perishable materials. Freeze-drying works by freezing the material first, then reducing the pressure and adding heat to allow the frozen water in the material to sublimate.The moisture in the pre-frozen material is directly sublimed from solid state (ice) to gaseous state (vapor), without melting, the finished products contain little water.

Freeze Dryer can be used to process nearly all kinds of food.

Under vacuum condition, material is freeze dried via principle of sublimation, compared to other food preservation methods, freeze dried products have many advantages:

Nutrition Facts

Since the material is dried under low temperature and low-oxygen (vacuum) conditions, the nutrients are basically unchanged, the heat-sensitive substances are especially prominent.

Freeze-dried foods, like frozen, retain virtually all their fresh-food taste and nutritional content.

Shape

Because it is the direct conversion of water from the solid phase to gaseous phase, the food architecture has not changed, during drying the space occupied by the ice crystals becomes pores, products are formed to be sponginess, without shrinking. Freeze-dried foods maintain their original shape and texture, unlike other dehydrated foods, which shrink and shrivel due to high-temperature processing.

Color

Since the drying is carried out under low temperature and low-oxygen (vacuum) conditions, the physical and chemical properties of the food haven't changed, mainly because there is no major change in the ability to respond to visible light after rehydration. Due to the effects of oxidation and enzymatic are very subtle, so the original color is easy to maintain.

Flavor

Because the aromatic components in the food remain in the amorphous concentrated part during the freezing process, the fragrance will not escape as the ice crystals vaporize.Freeze-drying removes the water only, not the flavor.

Solid material basically remains

Since the moving velocity of the sublimation vapor is very small, the object is basically at rest, and the mass loss of the solid material is negligible.

Light in weight

Freeze-dried foods have 98% of their water removed. This reduces the food's weight by about 90%. Because of its light weight per volume of reconstituted food, freeze-dried products are popular and convenient for hikers. More dried food can be carried per the same weight of wet food, and remains in good condition for longer than wet food, which tends to spoil quickly. Hikers reconstitute the food with water available at point of use.

Rehydration easy & fast

Because the moisture left a lot of pores after drying, so the rehydration is good, it only takes very short time to get rehydrated for more than 95%.

Freeze-drying removes water under low temperatures which keeps intactness of the moisture channels and food fibers. Just add water, the fresh material returns.

Convenient storage & long shelf life

Due to the high dehydration rate, no preservatives required, and a very long shelf life can be achieved at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration.The shelf life can exceed five years as long as the package is good. Cold chain is not needed for storage, because it's light in weight, the storage and transportation are much more convenient, and the recurring cost is low.